COB LED strips - Excellent lighting for any occasion

COB LED strips (Chips on Board LED) are a further development of conventional LED strips. In contrast to conventional LED strips, the LED chips in COB LED strips are applied directly to a carrier board. This results in high luminosity and uniform light distribution. The often unpleasant bright single light points are a thing of the past.

(For the freaks: Through this so-called area light source technology, the LED chips are applied to a mirrored metal substrate with a high degree of reflection and thus achieve a high efficiency).

Advantages and disadvantages of COB strip lighting

| Compared with traditional LED strips, COB LED strips have the following advantages: | However, there are also some disadvantages with COB LED strips that need to be considered: |

|

|

COB Strip Applications

COB LED strips are used in many applications, for example in the illumination of shop windows, in the automotive industry, in building lighting and in consumer electronics, as well as cove lighting in living spaces.

While in these applications in particular a diffuse and also attenuating cover was often used in conjunction with an aluminum profile in order to achieve uniformity, this can be dispensed with in the case of COB strips. This results in higher efficiency (system luminous efficacy).

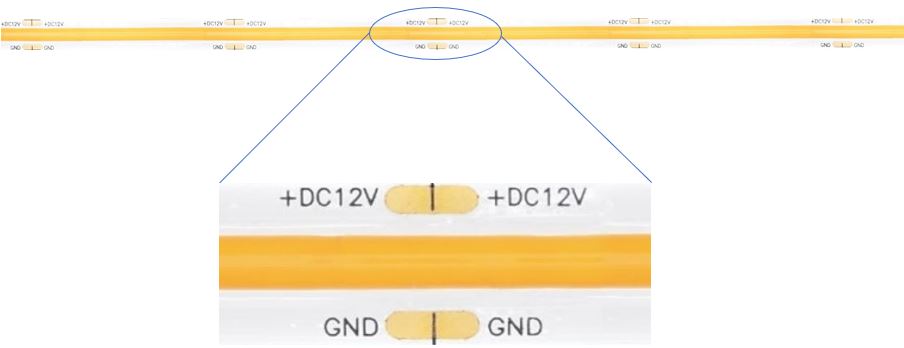

How can COB LED strips be separated?

To cut COB LED strips, you must make sure that you only cut them at the designated points (see imprint or manufacturer's data sheet), otherwise the LEDs may be damaged.

It is therefore advisable to follow the manufacturer's instructions and use clean, sharp scissors or a sharp knife. Briefly check for short circuit with a multimeter if necessary.

Please be sure to remove any cutting burrs. Avoid short circuits during further processing, insulate if necessary.